How to Read Ac Compressor Pressure Hihg and Low

Using Gauges for Troubleshooting

Gauge pressure is the first tool in Air-conditioning troubleshooting. The table below shows vii Judge Readouts that you may encounter. Use the Gauge Readout Tool separately or in combination with the table of Gauge Diagnostics for Air-conditioning troubleshooting.

Gauge Readout Tool

Normal Weather condition

Air in cooling system (insufficient suction)

Defective expansion valve

Excessive refrigerant

Moisture Intrusion

Refrigerant does non broadcast

Summary Tabular array of Guess Diagnostics

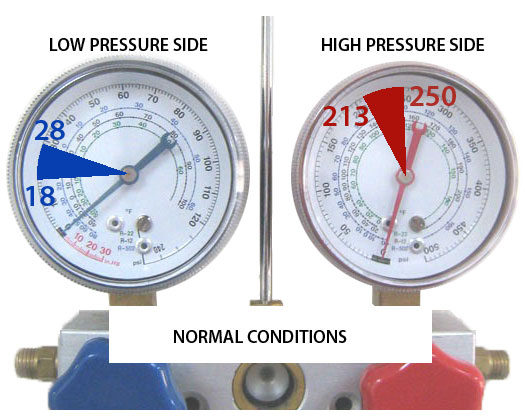

Normal Conditions

ane Atmosphere

Room Temperatures of thirty-38 C (86 - 96 F)

Engine speed of approx. 1500 rpm or about 75% of rated engine speed

Back to Height

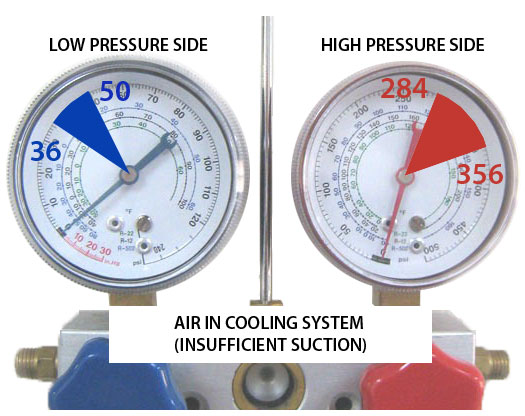

Air in cooling system (insufficient suction)

Pressure Range

Depression side: 36 to 50 psi

High side: 284 to 356 psi

Indications

Both pressures are Also HIGH

The low-side piping is not cold

Causes

Air in the system

Remedy

Evacuate the system

Replenish the refrigerant

Check the gauge readings

If prolonged operation with air in the organisation, the liquid tank must be replaced.

Dorsum to Height

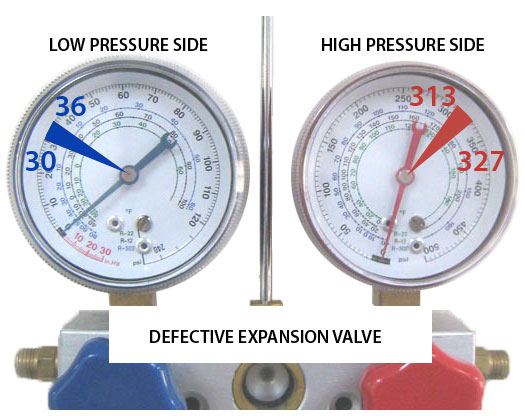

Defective expansion valve

Pressure level Range

Low side: xxx to 36 psi

High side: 313 to 327 psi

Indications

Both pressures are Likewise HIGH

Causes

Improper refrigerant charge

Defective expansion valve

Improper temperature sensor installation

Remedy

Verify refrigerant charge

Check temperature sensor installation and insulation

If the refrigerant charge is okay and the temperature sensor installation and insulation are right then replace the expansion valve.

Back to Height

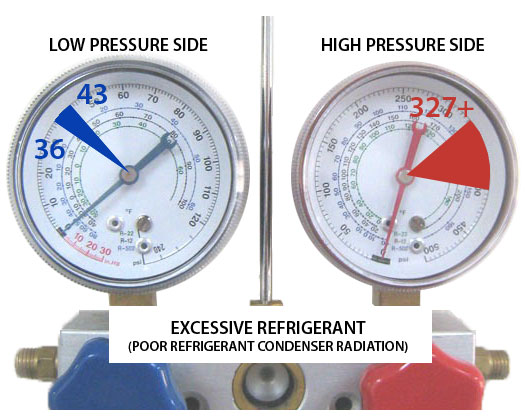

Excessive refrigerant

Pressure Range

Depression side: 36 to 43 psi

High side: 327+ psi

Indications

Both pressures are TOO High

Causes

Pressure increment due to excessive refrigerant

Insufficient condenser cooling

Remedy

Verify the refrigerant level

Clean the condenser

Check and arrange the fan belt and / or the condenser fan motors

Back to Meridian

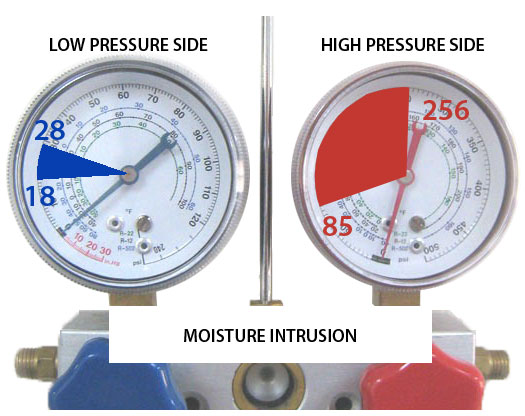

Moisture Intrusion

Pressure Range

Low side: eighteen to 28 psi

High side: 85 to 256 psi

Indications

Low pressure side alternates between a vacuum and normal pressure

Causes

Wet has frozen in the air conditioner system, clogging the expansion valve.

Remedy

Evacuate the organisation

Replace the receiver dryer

Recharge the arrangement

Back to Pinnacle

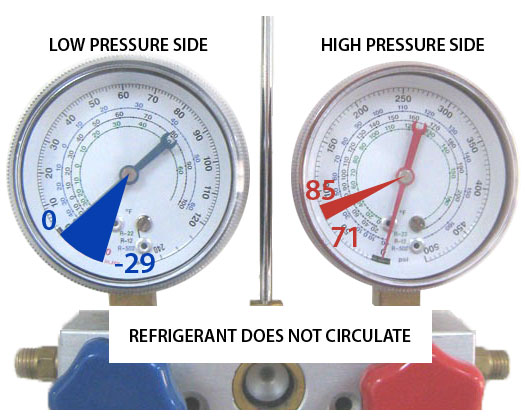

Refrigerant does not circulate

Force per unit area Range

Depression side: 0 to -29.99 psi

High side: 71 to 85 psi

Indications

Low pressure side becomes a vacuum

High pressure as listed to a higher place

Frost or condensation on the front and rear pipage connections of the receiver dryer or expansion valve

Causes

Air-conditioning organization is blocked by contagion or ice

AC system is shut off by defective expansion valve or tempeerature sensor

Air conditioning line from evaporator to compressor has kink in the line

Remedy

Stop OPERATION IMMEDIATELY

Check for contamination or water ice

If wet is found then evacuate the system

If the expansion valve is defective then supercede it

Replace receiver dryer

Recharge with refrigerant to proper level

Repair any kinked hoses

Back to Top

Summary Table of Gauge Diagnostics

Low Force per unit area Side is TOO Loftier

The low pressure side unremarkably becomes likewise high when the loftier pressure side is too loftier.

| Cause | Inspection | Remedy |

|---|---|---|

| Defective Thermoswitch | The magnetic clutch switch turns off before the outlet air temperature is sufficiently low. | Replace the thermoswitch |

| Poor Expansion Valve temperature sensor contact | The loftier and low force per unit area sides judge pressures equalize when the magnetic clutch is turned off (within a short time duration) | Replace Compressor |

| Expansion Valve opens as well far | Frost has adhered to the suction hose / piping | Install the temperature sensor confronting the low pressure pipe and comprehend with insulating record. |

| Clogged compressor suction filter | Compressor fitting is absurd but the depression pressure hose is not. | Remove and clean the filter. |

Low Pressure Side is Too LOW

| Cause | Inspection | Remedy |

|---|---|---|

| Insufficient Refrigerant | At that place is little temperature difference between the low and loftier pressure sides. | Repair any leaks and recharge the refrigerant to the correct levels. |

| Clogged liquid tank (receiver dryer, accumulator) | Considerable temperature departure between the inlet and outlet sides of the receiver dryer during operation. Also, tank may be frosted | Replace liquid tank (receiver dryer) |

| Clogged expansion valve | Expansion valve inlet side is frosted. Generally the depression side pressure is about vacuum. | Replace expansion valve. |

| Expansion valve temperature sensor gas leak (damaged capillary tube, etc..) | Expansion valve outlet side is chilled and depression pressure side is LOW. | Clean or replace expansion valve. |

| Chock-full or blocked pipage | Low pressure level readings subtract or a negative reading is shown. Indicates piping is clogged or blocked betwixt the evaporator curl and the compressor. A frost spot may indicate the point of blockage. | Clean or supervene upon piping. |

| Defective thermoswitch (cold command) | Evaporator is frozen showing ice along the confront of the coil, not merely frost on the manifolds of the gyre. | Adjust temperature sensing tube to a cooler part of the coil or supersede the thermoswitch. |

Loftier Pressure Side is TOO HIGH

| Crusade | Inspection | Remedy |

|---|---|---|

| Poor Condenser cooling | Muddy or clogged condenser fins, Cooling fans do not operate correctly. | Clean and / or repair the condenser cadre / fans. |

| Excessive refrigerant | Verify by estimate reading | Employ your refrigerant recovery equipment to capture excess refrigerant. Charge to the correct refrigerant levels. |

| Air in the system | Pressure is high on both loftier and low sides | Evacuate, vacuum and recharge with refrigerant. |

High Pressure Side is TOO LOW

| Crusade | Inspection | Remedy |

|---|---|---|

| Insufficient refrigerant | Lilliputian temperature divergence between the depression and high pressures. | Repair any leaks and recharge the refrigerant to the correct levels |

Source: https://www.perrinmfg.com/resources/gauge-diagnostics

0 Response to "How to Read Ac Compressor Pressure Hihg and Low"

Post a Comment